Neoprene is a synthetic rubber material made from the polymerization of chloroprene. It was first developed by DuPont in the 1930s and has since been used in various applications such as wetsuits, laptop sleeves, medical braces, and even car seat covers. Neoprene tubing, in particular, is used in various industries such as medical, electronics, and sports for its versatility and durability. In this article, we will focus on neoprene tubing, including its production, considerations regarding its use and manufacture, benefits, and various applications. Read More…

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber is your source for extruded, Molded, Die cut & Secondary fabrication work in rubber products, tubing and shapes made out of Silicone, Flurosilicone, Viton, Nitrile, Neoprene, EPDM, SBR,butyl & any custom compound. We offer our customers high quality, complex shapes and fast turn-around times.

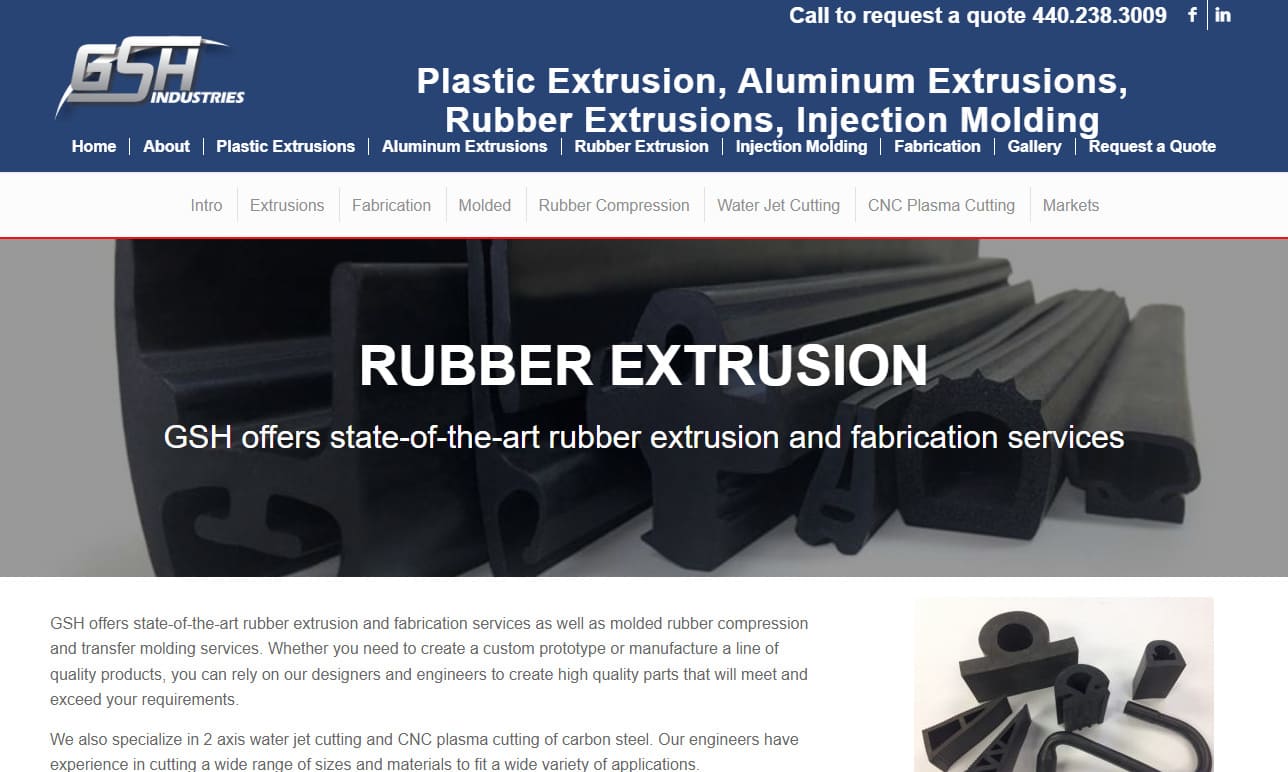

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

More Neoprene Tubing Manufacturers

Neoprene Tubing Production

Neoprene tubing, also known as polychloroprene tubing, is manufactured through sophisticated chemical engineering techniques. The process begins with the synthesis of chloroprene, which is then polymerized to form neoprene rubber—a synthetic elastomer prized for its durability and versatile performance. During production, chloroprene undergoes polymerization via emulsion, solution, or suspension methods. The selection of the polymerization process depends on the specific performance requirements and desired characteristics of the neoprene tubing, such as hardness, flexibility, and resistance levels.

To enhance the chemical and physical properties of neoprene tubing, manufacturers often add reinforcing agents, fillers, plasticizers, and curing agents. These additives can impart improved oil resistance, flame retardancy, color stability, and tensile strength. After blending, the material is extruded or molded into seamless tubing of various diameters and wall thicknesses, then vulcanized for enhanced elasticity and resilience.

Looking for detailed technical specifications or custom neoprene tubing production capabilities? Contact a neoprene tubing manufacturer to discuss extrusion options, custom sizes, and specialized formulations for unique applications.

Considerations Regarding Neoprene Tubing

When evaluating neoprene tubing for your project or application, it’s essential to consider several factors that impact cost, performance, and sustainability. These include:

- Health and Safety: Neoprene is generally safe for contact with skin, making it suitable for medical, laboratory, and food-grade tubing. However, individuals with latex allergies or sensitive skin should be aware that prolonged direct contact can occasionally cause mild irritation. Always confirm compliance with FDA, USP, or NSF standards if your application involves food, beverage, or medical use.

- Environmental Impact: The manufacturing of neoprene rubber tubing involves the emission of certain volatile organic compounds (VOCs) and other chemicals. Responsible suppliers may implement eco-friendly processes, waste minimization, and recycling programs to reduce their environmental footprint. If sustainability is a concern, inquire about “green” manufacturing methods or alternative elastomers, such as EPDM or silicone tubing.

- Production Challenges: Neoprene production can be energy-intensive, and the disposal of scrap materials or byproducts requires proper handling. Leading neoprene tubing manufacturers invest in state-of-the-art facilities to maximize efficiency, minimize waste, and meet regulatory requirements. For critical applications, request documentation on compliance with RoHS, REACH, or other relevant standards.

Want to compare the environmental and safety profiles of neoprene tubing versus alternative rubber or plastic tubing? Explore our guides on sustainable tubing materials and industry compliance standards for more insights.

Benefits of Neoprene Tubing

Neoprene tubing offers a range of valuable benefits that make it a top choice for industrial, commercial, and specialized applications. These advantages include:

- Chemical and Oil Resistance: Neoprene tubing is highly resistant to petroleum-based oils, greases, hydraulic fluids, solvents, and a variety of chemicals. This property makes it ideal for transferring fuels, coolants, and corrosive liquids in automotive, aerospace, and manufacturing environments.

- Abrasion and Weather Resistance: The durable nature of neoprene rubber provides exceptional resistance to abrasion, tearing, and external wear. It also resists degradation from ozone, sunlight (UV radiation), oxidation, and harsh weather conditions, making it suitable for demanding outdoor and marine applications.

- Flexibility and Elasticity: Neoprene maintains excellent flexibility, even at low temperatures, and can be stretched or compressed repeatedly without losing shape or functional integrity. This resilience is vital for dynamic systems where tubing must accommodate movement, vibration, or thermal expansion.

- Compression Set Resistance: Neoprene’s ability to retain its original form after being compressed over extended periods ensures lasting performance in seals, gaskets, and fluid transfer lines.

- Thermal Insulation: Thanks to its closed-cell structure, neoprene tubing provides superior insulation against heat and cold. This makes it a preferred material for protecting sensitive wiring, pipes, and components from extreme temperature fluctuations.

- Electrical Insulation: Neoprene is an effective dielectric material, offering reliable protection against electrical currents and static discharge. It’s widely used for insulating cables, wires, and electrical assemblies in industrial and commercial settings.

- Easy Handling and Installation: Neoprene rubber tubing is simple to cut, shape, and install using standard tools and fittings. It resists kinking and blockage, ensuring smooth fluid or gas flow in complex routing configurations.

- Versatility: Neoprene tubing is compatible with numerous fitting types, including barbed, compression, and push-to-connect fittings. It can be manufactured in a wide range of diameters, thicknesses, and colors to match specific system requirements.

Curious about the long-term durability or cost-effectiveness of neoprene tubing compared to silicone, PVC, or latex tubing? Read our in-depth tubing material comparison guides or contact a technical advisor for personalized recommendations.

Applications of Neoprene Tubing

Neoprene tubing’s unique balance of mechanical strength, chemical resistance, and flexibility makes it a preferred choice in numerous industries and applications. Common use cases include:

Industrial Applications

In industrial settings, neoprene tubing is an essential component for the safe and efficient transfer of fluids, gases, or powders. It’s commonly specified for use in:

- Automotive manufacturing: Fuel lines, coolant hoses, vacuum lines, and emission control systems.

- Oil and gas operations: Hydraulic tubing, lubrication systems, and chemical transfer lines.

- Process manufacturing: Flexible connections for pumps, compressors, and mixing systems.

- Protective cable and wire sleeving: Shielding electrical wiring from abrasion, heat, and chemical exposure.

Neoprene’s resistance to oils, chemicals, and abrasion ensures long service life and reduces maintenance costs in these demanding environments.

Medical Applications

Neoprene tubing is valued in the healthcare sector for its biocompatibility, flexibility, and ease of sterilization. Typical applications include:

- Medical device tubing (catheters, IV lines, peristaltic pump tubing)

- Respiratory therapy and anesthesia equipment

- Surgical tubing for fluid delivery and suction

- Protective sheathing for medical instruments

Always verify with your supplier that the neoprene tubing meets required medical or laboratory standards for sterilization and chemical compatibility.

Sports and Fitness Applications

In the sports and fitness industry, neoprene tubing’s flexibility and resistance to environmental stressors make it an attractive choice. Common uses include:

- Resistance bands and exercise tubing

- Weightlifting belts and grips

- Protective padding and joint supports

- Components for gym and exercise equipment

Because neoprene resists UV rays and sweat, it maintains performance and comfort over time, even with frequent use.

Electrical and Electronic Applications

As an electrical insulator, neoprene tubing offers reliable protection in environments subject to vibration, moisture, or chemical exposure. Use cases include:

- Insulation for wiring harnesses and electrical assemblies

- Protective sleeving for power cords and data cables

- Enclosure gaskets for electrical cabinets and equipment

- Shielding for sensitive electronics in harsh settings

Neoprene’s stable dielectric properties and resistance to aging make it a trusted material for electrical safety and equipment longevity.

Marine Applications

Marine environments demand materials that can withstand saltwater, UV radiation, and constant flexing. Neoprene tubing is a staple for:

- Boat fuel lines and bilge pump tubing

- Dock lines, bumpers, and marine fender covers

- Protective covers for ropes and hardware

- Seals and gaskets for watertight compartments

Looking for neoprene tubing with enhanced UV resistance or custom marine-grade specifications? Request a quote from a marine neoprene tubing supplier today.

Aerospace Applications

The aerospace industry relies on neoprene tubing for its ability to withstand temperature extremes, radiation, and mechanical stress. Typical aerospace uses include:

- Fluid transfer lines in aircraft and spacecraft

- Environmental control systems

- Protective sheathing for cables and wiring

- Seals, grommets, and vibration-dampening components

Compliance with stringent industry standards is critical—always confirm certifications and test data with your supplier for aerospace-grade neoprene tubing.

Additional Specialized Applications

Neoprene tubing’s versatility extends to a variety of specialty uses, including:

- Laboratory fluid handling and sampling lines

- Food and beverage dispensing systems (subject to FDA approval)

- HVAC systems for insulation and vibration damping

- Plumbing and water treatment equipment

- Robotics and automation systems

- Protective covers for bicycle and motorcycle cables

Not sure if neoprene tubing is the right fit for your unique application? Consult our application experts or browse real-world case studies for inspiration and guidance.

Choosing The Correct Neoprene Tubing Supplier

Selecting the ideal neoprene tubing supplier is vital to ensuring optimal product performance, cost-effectiveness, and reliable delivery for your project. Here are key factors to consider when evaluating neoprene tubing providers:

- Product Range: Does the supplier offer a comprehensive selection of neoprene tubing sizes, colors, and hardness levels? Can they provide custom formulations or specialty grades, such as flame-retardant, FDA-compliant, or high-temperature tubing?

- Manufacturing Capabilities: Assess whether the supplier has advanced extrusion and molding equipment, in-house testing labs, and quality control systems. This ensures consistent product quality and adherence to tight tolerances.

- Certifications and Compliance: Review documentation for certifications such as ISO 9001, FDA, USP Class VI, RoHS, and REACH. These demonstrate a commitment to quality and regulatory compliance—especially important for medical, food, and aerospace applications.

- Lead Time and Inventory: Consider the supplier’s ability to maintain stock of standard tubing and accommodate rush orders or custom runs. Reliable supply chains minimize downtime and ensure timely project completion.

- Technical Support and Customer Service: Look for suppliers with knowledgeable technical staff who can assist with application engineering, material selection, and troubleshooting. Responsive customer service is critical for resolving issues quickly.

- Pricing and Value: While cost is a consideration, focus on total value—including quality, consistency, and after-sales support. Request quotes from multiple suppliers to compare pricing, but also weigh service and expertise.

To ensure you have the most beneficial outcome when purchasing neoprene tubing from a neoprene tubing supplier, it is important to compare several companies using our directory of neoprene tubing suppliers. Each neoprene tubing supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each neoprene tubing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple neoprene tubing companies with the same form.

Ready to find a neoprene tubing supplier that fits your specific requirements? Browse our directory of verified neoprene tubing manufacturers and request custom quotes now. Need advice on selecting the right grade or size? Contact our technical support team for personalized recommendations or explore our neoprene tubing selection guides for detailed information.

Frequently Asked Questions About Neoprene Tubing

- What is the temperature range for neoprene tubing?

Most neoprene tubing is rated for continuous temperatures from -40°F to 200°F (-40°C to 93°C), with some specialty formulations extending higher. Always verify the temperature limits for your intended use. - Is neoprene tubing suitable for food and beverage applications?

Certain neoprene tubing is FDA or NSF compliant for food and beverage contact. Confirm with the supplier and request certification for food-grade use. - How does neoprene tubing compare to silicone or PVC tubing?

Neoprene offers superior oil and chemical resistance compared to PVC, with better abrasion resistance than silicone. However, silicone tubing excels in extreme temperature and medical uses. Review our material comparison articles for an in-depth analysis. - Can neoprene tubing be sterilized?

Neoprene can be sterilized using certain methods (such as autoclaving or chemical sterilants), but always verify compatibility with your intended sterilization process. - Does neoprene tubing have any odor?

New neoprene tubing may emit a mild rubber odor, which typically dissipates over time or with initial cleaning. If very low odor is required, request low-VOC or specialty formulations.

Related Resources and Next Steps

- Neoprene Tubing Product Catalog – Browse full specifications, grades, and sizes

- Custom Neoprene Tubing Fabrication Services – Learn about bespoke solutions

- Neoprene Tubing Material Safety Data Sheets (MSDS) – Download for compliance and safety

- Industry Application Guides – Explore use cases by sector

- Tubing Installation and Maintenance Best Practices

- Contact Technical Support – Get help with selection and troubleshooting

Still have questions about neoprene tubing, its properties, applications, or suppliers? Contact us today for expert guidance or request a quote to get started on your next project.

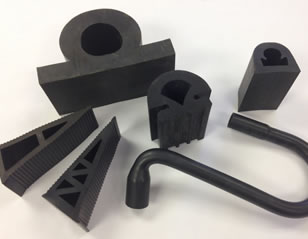

Rubber Extrusions

Rubber Extrusions Rubber Molding

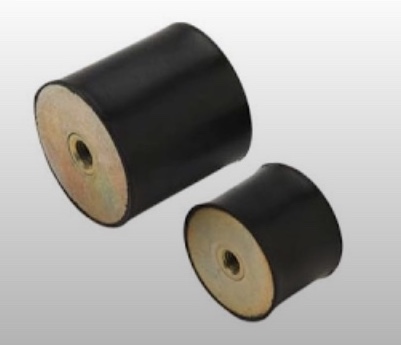

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

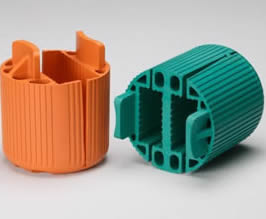

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services