Rubber tubes, also known as rubber hoses or rubber piping, are used for the transport and circulation of liquid and gasses in households and industries. Rubber exists in both natural and synthetic forms, and both forms are used for making rubber tubes. Read More…

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber is your source for extruded, Molded, Die cut & Secondary fabrication work in rubber products, tubing and shapes made out of Silicone, Flurosilicone, Viton, Nitrile, Neoprene, EPDM, SBR,butyl & any custom compound. We offer our customers high quality, complex shapes and fast turn-around times.

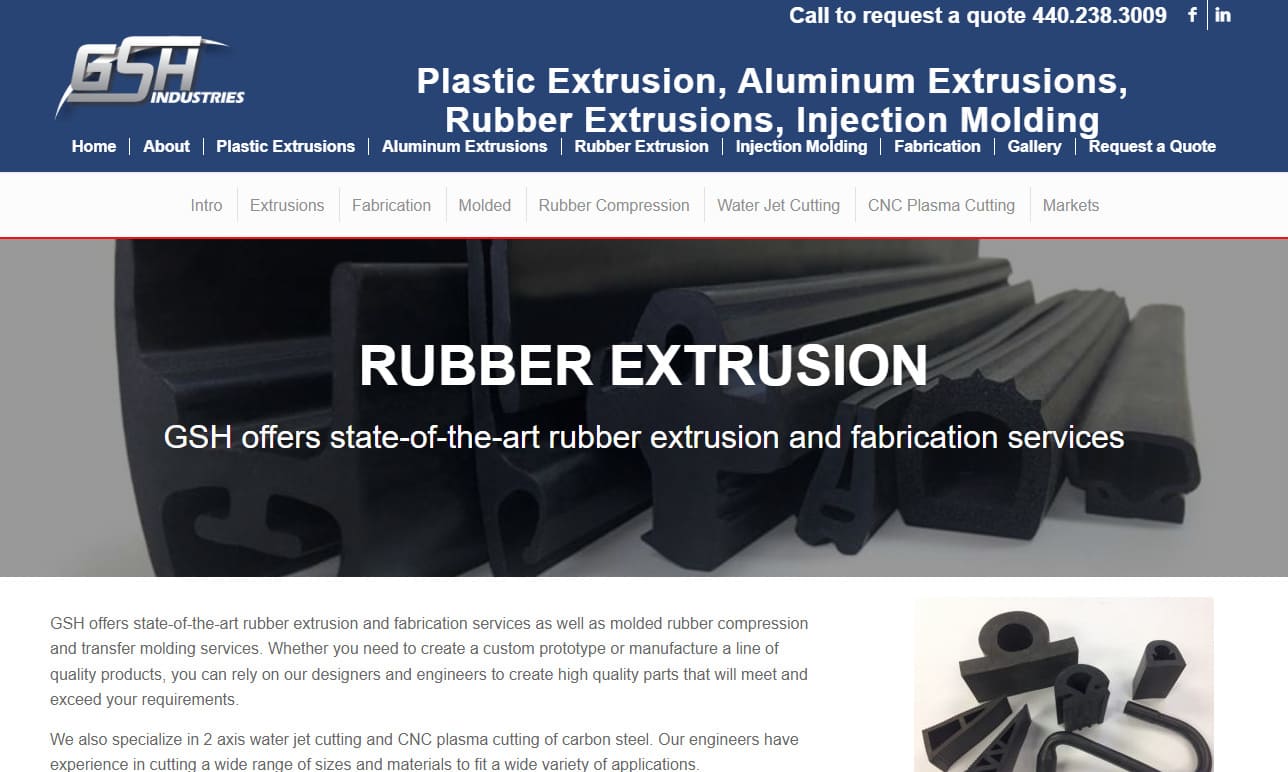

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

More Rubber Tube Manufacturers

Whether natural or synthetic material is used rubber tubing, it is important that the rubber selected is extremely flexible, dependable, and appropriate for use in specific processes such as hydraulic or pneumatic equipment operation, in medical equipment, and food production. Rubber tubes are used in many specialized applications in industries therefore, they are manufactured in many different diameters and wall thickness.

Types of Rubber Material Used

Both natural and synthetic rubbers are used for rubber tubing. Natural rubbers are often the best choice for use as they have high resilience, tear resistance, and temperature resistance. Natural rubbers such as polyisoprene and latex are commonly used since they exhibit excellent tear and chemical resistance. However, natural rubbers have weak ozone and oil resistance. As a result, synthetic rubbers came into business. Each synthetic rubber exhibits specific properties and is used for specific applications. A few synthetic rubber materials are discussed here.

Isoprene

Isoprene is a derivative of natural rubber. It is fatty acid and protein-free with high abrasion resistance.

Polyurethane

Polyurethane is also commonly known as thermoplastic polyurethane. This material exhibits excellent abrasion and chemical resistance. It also has excellent performance on low temperatures with good elasticity and mechanical properties.

Silicone Rubber

Silicone rubber, commonly known as Si rubber, shows excellent chemical-, temperature-, flame-, and weather-resistance.

Process for Making Rubber Tubing

Rubber tubing is created by using one of the two processes. The first process is the extrusion process and the other is the Mandrel process. In the extrusion process, the rubber is placed in dies, while in the Mandrel process, the rubber strips are wrapped around the pipes and heated. We discuss each process in greater detail below.

Extrusion Process

Unvulcanized and soft rubber compounds are used in the extrusion process (the process of forming rubber tubing by forcing it through a small opening) of rubber tubing. The parts that are formed through this process are soft and pliable at first and then they are vulcanized after the extrusion. The various steps involved in the extrusion process are listed below:

- The process starts by feeding the rubber compound into the extruder.

- This unvulcanized rubber is then passed onto the screw that moves and puts it into the die.

- The rubber of equal diameter and proportion is fed into the die, where there is an increase in temperature and pressure.

- This increase in temperature and pressure helps in swelling of the rubber compound and is set according to its type and hardness.

- After the extrusion process, the rubber is then vulcanized where it is treated with sulfur at high temperatures in order to enhance various beneficial traits like elasticity and weather resistance.

- Other modern techniques are also used to perform the vulcanization process such as microwave heating, and salt baths.

Mandrel Process

- The rubber used in the mandrel process is delivered in rolls of rubber strips. The thickness and color of the rubber is determined by the thickness and color of the sheet.

- The next process is milling, in which rubber strips are run through a mill to heat and soften the rubber to ensure its smooth texture.

- After milling, the rubber is fed into a cutting machine where it is cut into strips. The cutting machine cuts the rubber into strips of equal width and thickness.

- The cut rubber strips are wrapped on a lubricated mandrel, or cylinder rod. This process is important for creating a regular thickness of the strips.

- Afterwards, a reinforcement layer is added onto the rubber strips. This material is made of a high-strength synthetic and the layering depends on the amount of pressure that this rubber tube may have to endure.

- For further improvement in strength, additional wire is added onto these strips.

- A wet nylon tape is applied to the width of the outer layer of the rubber strips.

- This nylon tape will shrink and compress the materials together.

- The vulcanization process is then done by placing these rubber strips in an autoclave, in which steam is used to cure the rubber and make it elastic.

- One end of the tube is sealed tightly for its removal from the mandrel; water is pumped into it to separate it.

Types of Rubber Tubing

Food-Grade

Food-grade rubber tubing should be free of contamination and can withstand the high temperature, high pressure, and chemicals that are used in food processing.

Medical-Grade

Medical grade rubber tubings should also be safe to use for patients. This rubber tubing should be free of contaminants and degradation and can be used in various applications.

Conductive Tubing

Conductive tubing is used to control static electricity buildup and serves as electromagnetic interference or radio-frequency interference shielding. This tubing is used to move gasses and liquids near electrically-charged equipment.

Microbore Rubber Tubing

Microbore rubber tubing is used in the medical industry, particularly in intravenous lines for the flow of drugs into the body. This should be contaminant- free and is available in extremely small sizes.

Air Rubber Tubing

Air rubber tubing is used to move pressurized air to valves, tools, and actuators.

Chemical Rubber Tubing

Chemical rubber tubing is used for the movement of chemicals, fluids, acids, and other toxic substances of hydraulic fluids.

Heat Shrink

Heat shrink tubing is used to insulate, protect, and repair wires, making them more useful.

Fabric-Reinforced

Fabric-reinforced tubing comes in three parts and is resistant to oils, abrasion, and has a firm appearance.

Non-Reinforced Rubber Tubing

Non-reinforced rubber tubing is used for low-pressure applications. This tubing is soft, flexible, lightweight, and durable. It is used in the food industry and for pneumatic applications.

Applications of Rubber Tubing

- Rubber tubings are used in the automotive industry for fuel lines, hose, and cooling system parts.

- It is also used in agriculture for collecting debris, moving grains, and feeding.

- The aerospace industry also uses rubber tubing for fluid motion and as a connector between metal tubings.

- It is widely used in food processing, medical industry, and pharmaceutical applications.

- Rubber tubing is also used for the discharge of coolant, oil, fuel, and other liquids by chemical manufacturers and other industries utilizing these materials.

Choosing the Correct Rubber Tube Manufacturer

To make sure you have the most productive outcome when purchasing rubber tubes from a rubber tube manufacturer, it is important to compare at least 5 companies using our list of rubber rube manufacturers. Each rubber tube manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each rubber tube company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple rubber tube companies with the same form.

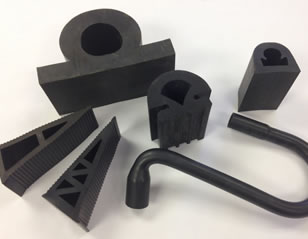

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

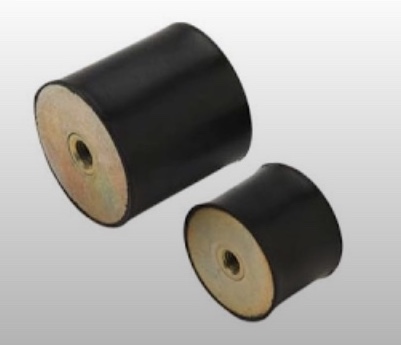

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

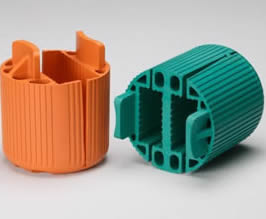

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services