It remains a registered trademark of DuPont Dow Elastomers. Fluoroelastomers are synthetic elastomers that are integrated with fluorine in concentrations of at least 66% in order to boost the material’s chemical resistance. Read More…

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

At Kent Rubber Supply Co., we specialize in providing high-quality rubber tubing solutions to meet the diverse needs of our customers. With decades of experience in the industry, we take pride in offering a comprehensive selection of durable, reliable, and customizable rubber tubing products. Our tubing is designed to perform in a wide range of applications, including industrial, commercial, and...

National Rubber is your source for extruded, Molded, Die cut & Secondary fabrication work in rubber products, tubing and shapes made out of Silicone, Flurosilicone, Viton, Nitrile, Neoprene, EPDM, SBR,butyl & any custom compound. We offer our customers high quality, complex shapes and fast turn-around times.

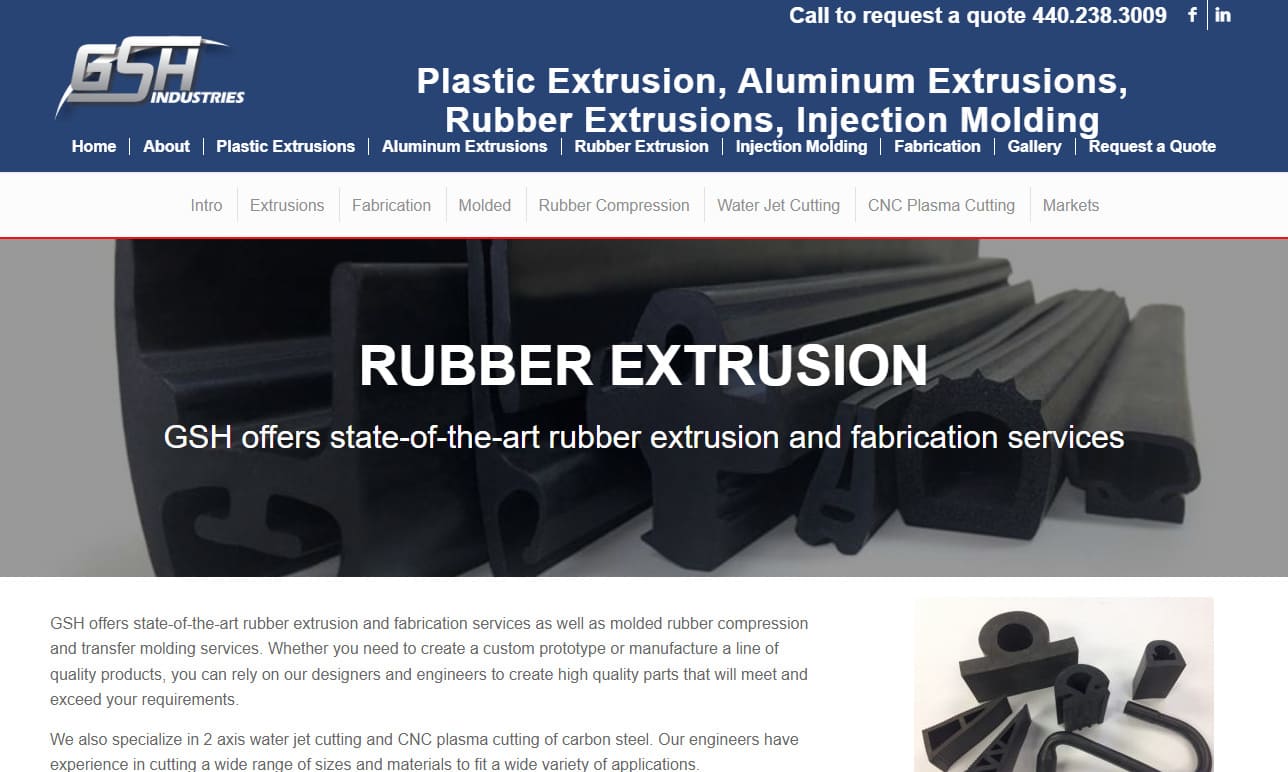

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

More Viton Tubing Manufacturers

Viton tubing is prized primarily because of its resistance to petrochemicals, particularly diesel and other fuel varieties. For this reason, Viton performs very well and is frequently used in engine fuel line systems. Unlike natural rubber tubing, which can degrade when brought into contact with petrochemical products in sufficient quantities, Viton retains its integrity when exposed to petrochemical products.

Viton is engineered to perform well at high temperatures; it can function without signs of degradation at temperatures as high as 200° C. It is also resistant to many oils, lubricants and mineral acids as well as exposure to ozone. Despite these qualities of high performance, Viton is not without its defects as an elastomeric utility. Viton's low temperature performance is very poor; when exposed to low enough temperatures for long enough periods of time, Viton can become cracked, which in fuel lines poses an extremely dangerous hazard.

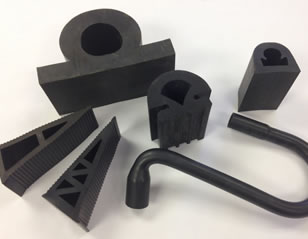

Viton is an example of black rubber tubing, most varieties of which are applied in industrial processes or in other situations in which the tubing will be exposed to harsh conditions. One common method of Viton tubing manufacture is extrusion. The extrusion process involves forcing a raw material through a die in order to shape it into a usable product. In Viton extrusion, the process begins with a collection of raw Viton in a hopper suspended above a conveyance channel. When the Viton is released into the conveyance channel, a long shearing screw forces the Viton down the channel as it turns.

The friction and pressurization caused by the turning of the screw causes the Viton to become molten. Once molten, the Viton is ready to be forced through the extrusion die at the end of the conveyance channel. A die, in the case of extrusion, is a specially shaped hole in a metal plate that gives a material its shape. When molten Viton is forced through an extrusion die, it takes its shape and emerges on the other side of the die as newly extruded Viton tubing. The tubing can then be cut to length and prepared for shipment to customers or for additional processing if necessary.

Rubber Extrusions

Rubber Extrusions Rubber Molding

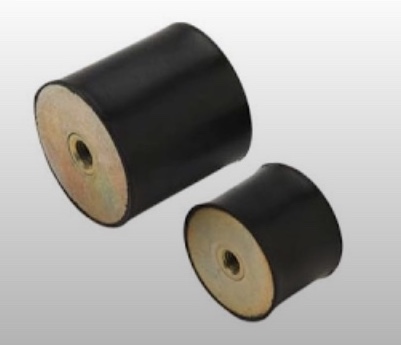

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

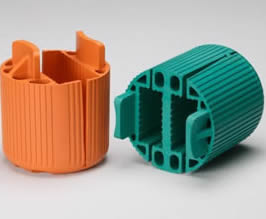

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services