Conductive rubber tubing is a versatile and highly useful material used in various industries, including electronics, automotive, aerospace, and medical.Its primary purpose is to provide electrical conductivity, grounding, and shielding.This article will discuss various methods used to create conductive rubber tubing, various types of conductive rubber tubing, and explain why a particular manufacturing method or type may be chosen. This article will subsequently discuss considerations regarding conductive rubber tubing, the benefits of conductive rubber tubing, and detail many applications of conductive rubber tubing.Read More…

We are rubber tubing experts, and we have been since our founding in 1954. We serve the entire world with quality tubing products right from the heart of Pennsylvania.

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

Manufacturer of standard and custom rubber tubing. Made of EPDM, neoprene, nitrile, dense, recovery sponge rubber and silicone compounds. Secondary processes such as die cutting, notching, and glue splicing are offered.

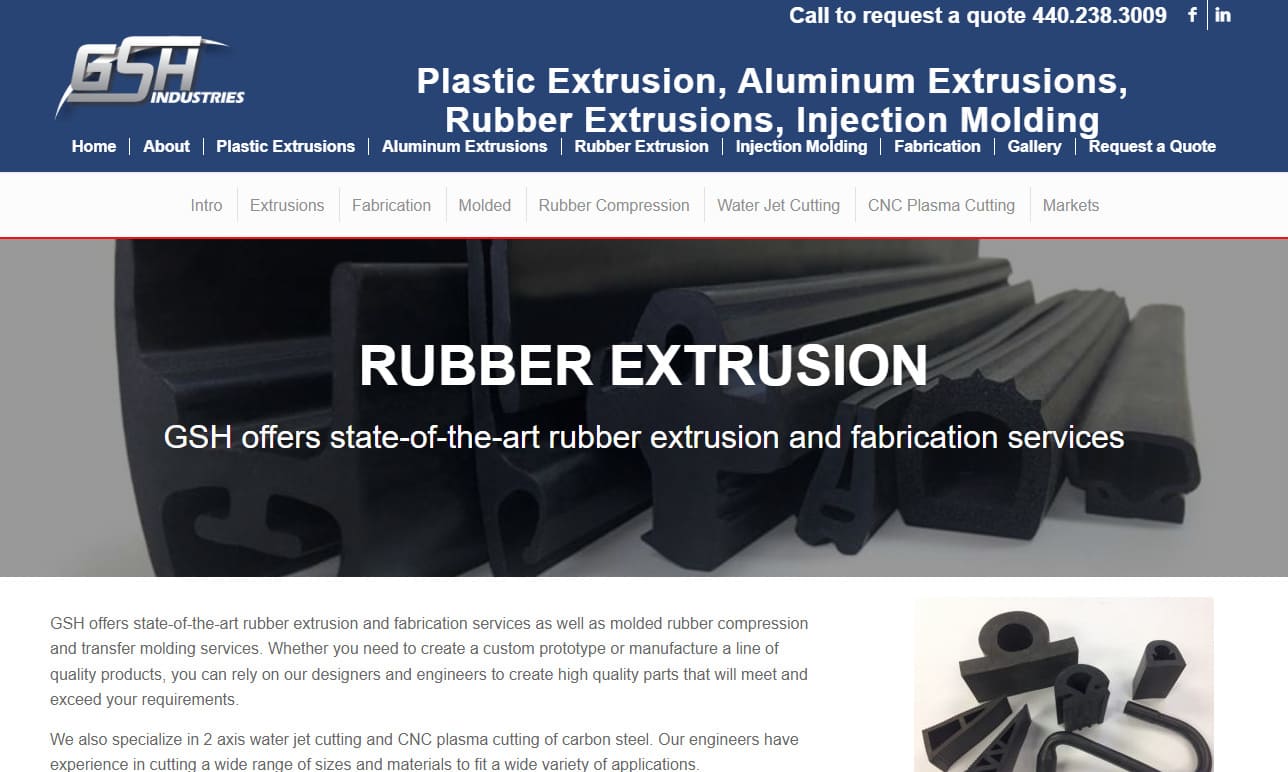

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

Since 1963, we have concentrated on elastomers. Specifically, we are a full service custom rubber tubing manufacturer that produces engineered high performance elastomers such as extrusions, moldings, rubber tubing and custom assemblies. We offer silicone tubing in many compounds, as well as rubber hose, Viton tubing and EPDM tubing. Your tubing will be fabricated to exacting tolerances.

More Conductive Rubber Tubing Manufacturers

Creating Conductive Rubber Tubing

To create conductive rubber tubing, the first step is to select the appropriate type of rubber, which can range from natural rubber to silicone, nitrile, or other synthetic rubbers. Conductive materials are then added to the rubber, which can vary depending on the intended use. Carbon black is a common conductive material used in rubber products due to its low cost and excellent electrical conductivity. Other materials such as graphite or metal particles may be added for specific applications.

Once the conductive material is added, the mixture is blended until it forms a uniform consistency. The resulting material can be molded into the desired shape and cured at high temperatures to create a stable, durable material.

Methods to Produce Conductive Rubber Tubing

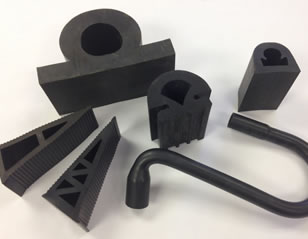

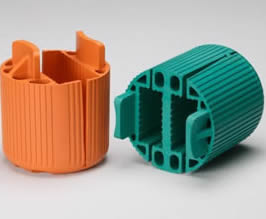

There are various methods available to produce conductive rubber tubing, including extrusion, compression molding, and injection molding. Extrusion is the most common method used to create conductive rubber tubing. It involves forcing the material through a die to create a specific shape. Compression molding is a method that involves heating the material and compressing it into a specific shape using a mold. Injection molding is another method used to create conductive rubber tubing. It involves melting the material and injecting it into a mold to form the desired shape.

The choice of method used depends on various factors, including cost, production speed, and quality control. Extrusion is the most cost-effective method, while compression molding is better suited for larger, more complex shapes. Injection molding is ideal for high-volume production runs.

Types of Conductive Rubber Tubing

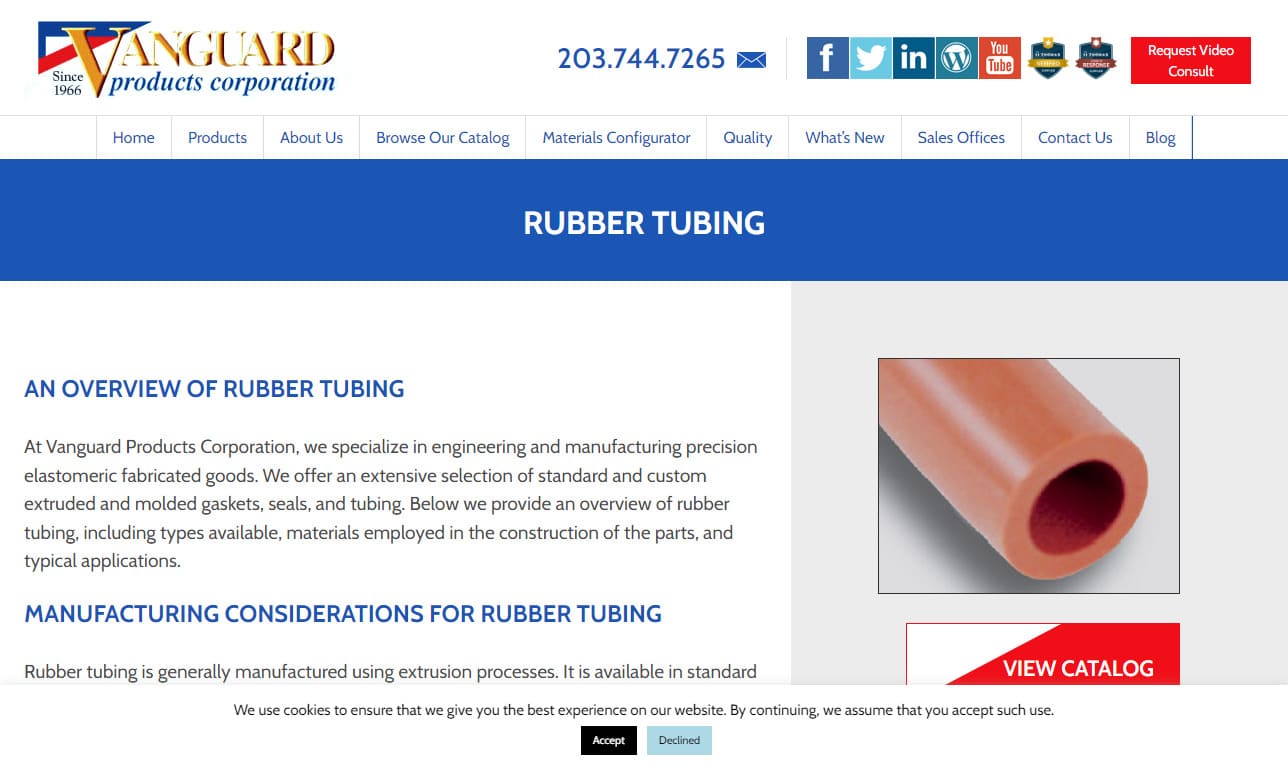

There are various types of conductive rubber tubing available, each with different levels of conductivity, elasticity, and durability. For example, silicone rubber tubing is ideal for applications that require high temperature resistance and excellent flexibility. Fluorosilicone rubber tubing is more resistant to chemicals and solvents than silicone rubber tubing. Ethylene propylene diene monomer (EPDM) rubber tubing is ideal for outdoor applications due to its excellent resistance to UV rays, ozone, and weathering.

Considerations Regarding Conductive Rubber Tubing

While conductive rubber tubing has many advantages, there are also negative considerations associated with it. One concern is the potential health and safety hazards associated with its production and use. The materials used to create conductive rubber tubing can be hazardous, and exposure to them can cause health problems. Another concern is the environmental impact of disposing of conductive rubber tubing.

Benefits of Conductive Rubber Tubing

Despite these concerns, conductive rubber tubing provides many benefits, as detailed below.

Electrical Conductivity

Conductive rubber tubing has excellent electrical conductivity, making it an ideal material for applications where grounding and shielding are important.

Flexibility

Conductive rubber tubing is highly flexible and can be molded into various shapes and sizes, making it suitable for a wide range of applications.

Durability

Conductive rubber tubing is highly durable and can withstand exposure to extreme temperatures, chemicals, and UV radiation without degrading or losing its electrical conductivity.

Resistance to Abrasion

Conductive rubber tubing has excellent resistance to abrasion and wear, making it ideal for use in harsh environments where materials are subjected to frequent contact and friction.

High-Temperature Resistance

Conductive rubber tubing can withstand high temperatures, making it an ideal material for use in applications that require exposure to high heat.

Chemical Resistance

Conductive rubber tubing has excellent resistance to chemicals, making it an ideal material for use in harsh chemical environments.

Anti-Static Properties

Conductive rubber tubing has anti-static properties that help to dissipate static electricity, making it ideal for use in applications where static discharge is a concern.

Easy to Process

Conductive rubber tubing is easy to process and can be manufactured in various forms such as extruded, molded, or die-cut.

Applications of Conductive Rubber Tubing

Conductive rubber tubing has many applications across various industries, including:

Electronics

Conductive rubber tubing is used extensively in the electronics industry to provide shielding and grounding for sensitive components. It is also used in electrical connectors, cables, and in the manufacturing of circuit boards.

Automotive

Conductive rubber tubing is used in the automotive industry to provide grounding and shielding in electrical systems. It is also used in gaskets and seals for various engine components.

Aerospace

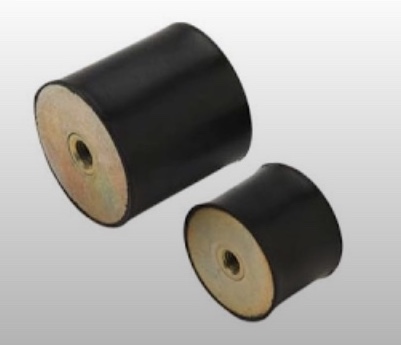

Conductive rubber tubing is used in the aerospace industry for vibration dampening and sealing applications. It is also used in electrical systems to provide grounding and shielding.

Medical

Conductive rubber tubing is used in medical equipment such as electrodes and sensors. It is also used in prosthetics and orthotics to provide conductivity for nerve stimulation.

Robotics

Conductive rubber tubing is used in robotics to provide a flexible and conductive material for sensors and connectors. It is also used in grippers and end effectors to provide a secure grip and electrical conductivity.

Industrial

Conductive rubber tubing is used in industrial settings to provide a conductive material for conveyor systems, rollers, and other applications where electrical conductivity is necessary.

Defense

Conductive rubber tubing is used in defense applications to provide grounding and shielding for sensitive electronic equipment. It is also used in gaskets and seals for various components.

Consumer Goods

Conductive rubber tubing is used in various consumer goods, such as in the production of wearables, such as smartwatches and fitness trackers. It is also used in gaming controllers and other electronic devices.

Choosing the Right Conductive Rubber Tubing Manufacturer

To ensure you have the most productive outcome when purchasing conductive rubber tubing from a conductive rubber tubing manufacturer, it is important to compare several companies using our directory of conductive rubber tubing manufacturers. Each conductive rubber tubing manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each conductive rubber business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple conductive rubber companies with the same form.

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services