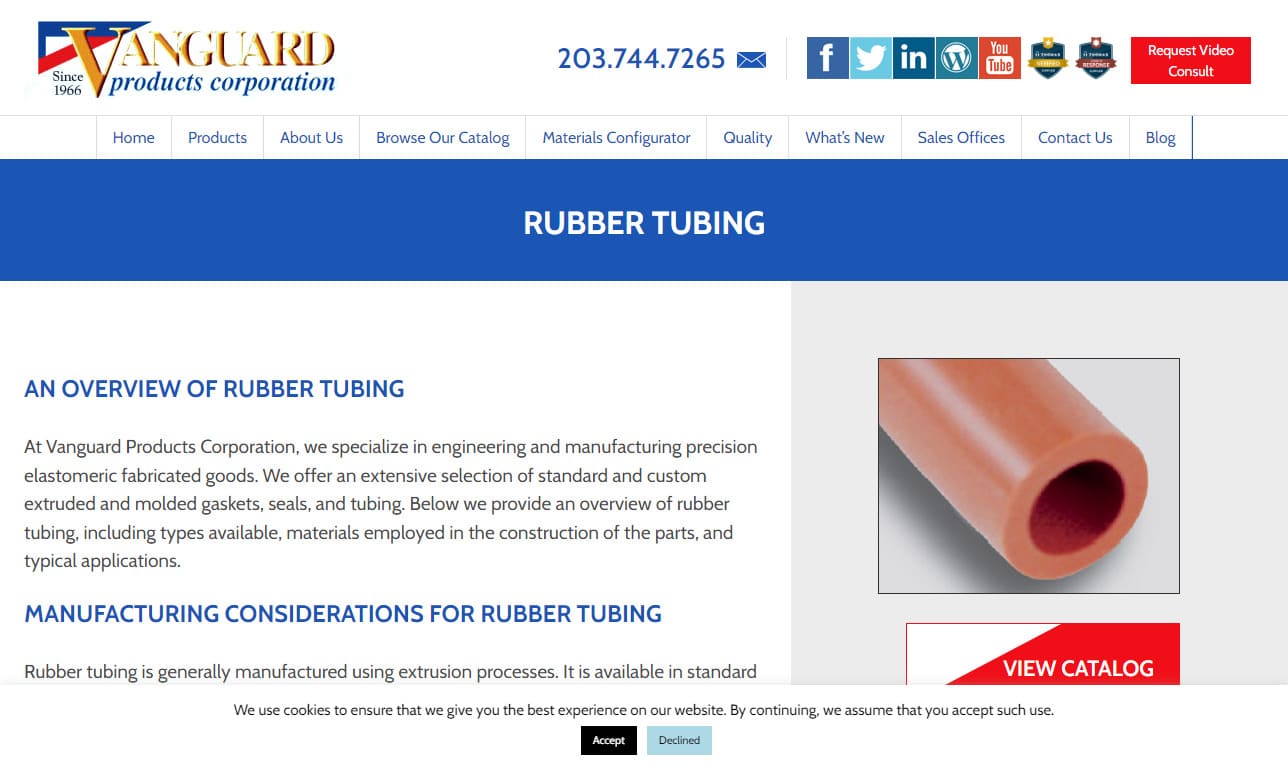

Rubber tubing is used to move gasses and liquids. Flexible rubber tubing is useful in areas where pipelines would get bent or twisted. Flexible tubing has strong walls that can support itself. Read More…

We are rubber tubing experts, and we have been since our founding in 1954. We serve the entire world with quality tubing products right from the heart of Pennsylvania.

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

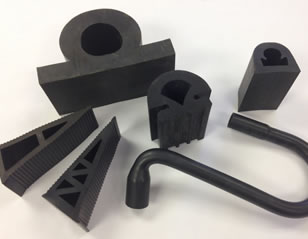

Manufacturer of standard and custom rubber tubing. Made of EPDM, neoprene, nitrile, dense, recovery sponge rubber and silicone compounds. Secondary processes such as die cutting, notching, and glue splicing are offered.

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

Since 1963, we have concentrated on elastomers. Specifically, we are a full service custom rubber tubing manufacturer that produces engineered high performance elastomers such as extrusions, moldings, rubber tubing and custom assemblies. We offer silicone tubing in many compounds, as well as rubber hose, Viton tubing and EPDM tubing. Your tubing will be fabricated to exacting tolerances.

More Flexible Rubber Tubing Manufacturers

Like all the other rubber tubings, flexible rubber tubing can be made from synthetic rubber or natural rubbers like latex and polyisoprene. Natural materials are more elastic than synthetic rubbers. Another characteristic of these natural materials is that they are hygienic in nature. These materials are hygienic, and used widely in the food and medical industries accomodate saftey concerns.

On the other hand, synthetic materials are resistant to tears and work will with oils. Therefore, synthetic materials are used for oils, chemicals, and other diluted acids where natural rubber tubings fail.

Characteristics of Flexible Rubber Tubing

- Flexible rubber tubing are made of natural or synthetic material.

- Rubber is stretchy and flexible, meaning it’s resistant to tears, deformation, and twisting.

- Flexible rubber tubing can withstand more extreme temperatures.

- Flexible rubber tubing are long-lasting.

Materials used for Flexible Tubing

Most of the material needed to manufacture flexible rubber tubing comes from a special elastomeric resin. This resin is elastic, soft to touch, and resilient when thick. Other materials that are used for flexible tubing include:

Thermoplastic Rubber

Thermoplastic rubber provides the strength of plastic and the flexibility of rubber. It is a versatile material that can withstand high temperatures. Thermoplastic rubber is used in high pressure hydraulic systems, chemical fuming processes, and other pressured gas applications.

PVC

PVC material is flexible and crush resistant. But this material is suitable for indoors only as high temperature and humidity can damage it.PVC is light-weight and helps direct the flow of liquids and gasses.

Polyurethane

Polyurethane is good for outdoor use because it deals well with temperature, humidity, chemicals, and abrasion. It is widely used in agriculture, industrial, mining and the lumber industry.

Neoprene

Neoprene is an inexpensive option that works well with oil, grease and high temperatures.

Silicone

.Silicone is a highly durable, flexible, and a versatile option in tube manufacturing. Silicone can retain its shape even at high temperatures therefore, it is widely used in automotive and exhaust industries.

Polyethylene

This material is durable, resistant to high pressure and kinks. Polyethylene is resistant to chemicals also. This material is used in high velocity water treatment plants, and wastewater plants.

Methods for Manufacturing Flexible Rubber Tubing

There are three general methods for manufacturing flexible rubber tubing.

Molding

Molding process forms halves of the tube separately. Liquid rubber is poured into molds and pressed into the tubes. The halves are then attached to each other.

Extrusion

Extrusion is done by forcing the raw rubber material into an extruder or extrusion die.

Dipping

Dipping or latex tubing is the most commonly used process. A cylindrical rod of desired diameter is dipped into liquid rubber material. It is slid out of the tube after the liquid rubber dries.

In all three processes, the rubber is cured and processed. Sometimes vulcanization of rubber is done in order to achieve desired consistency and shape of the tubing.

Types of Flexible Rubber Tubings

Red Natural Rubber

Red natural rubber is manufactured from natural rubber, and is used to transfer liquids, diluted acids, and gasses. It is a strong material, with excellent electrical properties. but doesn’t wear with oil or minerals. But it shows poor ozone, minerals, and oil resistance.

Silicone Rubber

Silicone rubber tubing has increased tensile strength and bacterial resistance. Therefore, it is safe for food and medical use. Silicone rubber tubing is resistant to temperature, ozone and weathering.

Neoprene Rubber

Neoprene rubber is a long-lasting rubber used for liquids and is stubbornly weather-resistant. This rubber can workwell for petroleum, but isn’t as useful for electrical insulation.

Nitrile Rubber

Nitrile rubber is a synthetic rubber that is resistant to fuels, oils, and other chemicals. It is used to transport gas, lubricants, and petrochemicals in pipelines. Nitrile rubber has high tear strength and abrasion resistance but is not good for electrical purposes.

Latex Rubber

Latex rubber is incredibly stretchy and flexible. It won’t become deformed even after continuous stretching. It is used for medical purposes, peristaltic and dosing pumps.

Applications of Flexible Rubber Tubings

- Flexible rubber tubings are widely used in the food and beverage industry.

- Medical and pharmaceutical industry use flexible tubing for sterile equipment

- Automotive, exhaust, and marine industries use these tubings for various applications.

- Agriculture industry uses plastic tubing fo rirrigation. This tubing is also used in hydraulic and peristalic pumps.

- Aerospace and wastewater treatment plants use these plastic tubes for liquid transfer.

Choosing the Right Flexible Rubber Tubing Manufacturer

To make sure you have the most beneficial outcome when purchasing flexible rubber tubing from a flexible rubber tubing manufacturer, it is important to compare at least 5 companies using our list of flexible rubber tubing manufacturers. Each flexible rubber tubing manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each flexible rubber tubing business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple flexible rubber tubing businesses with the same quote.

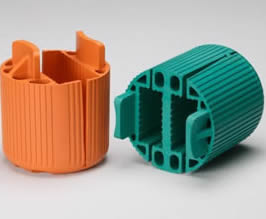

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

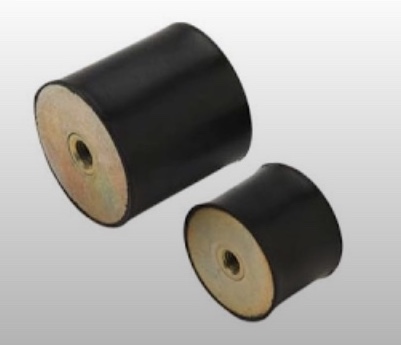

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services