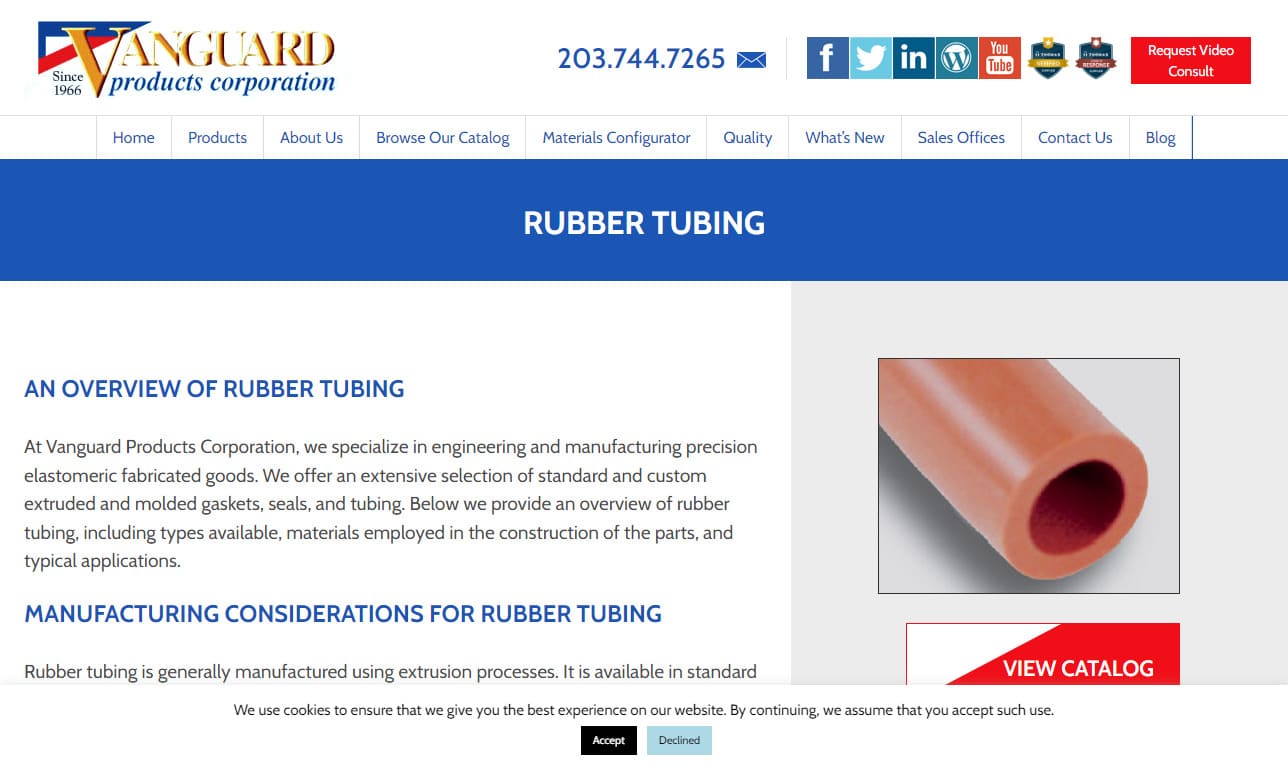

Neoprene is a synthetic rubber material made from the polymerization of chloroprene. It was first developed by DuPont in the 1930s and has since been used in various applications such as wetsuits, laptop sleeves, medical braces, and even car seat covers. Neoprene tubing, in particular, is used in various industries such as medical, electronics, and sports for its versatility and durability. In this article, we will focus on neoprene tubing, including its production, considerations regarding its use and manufacture, benefits, and various applications. Read More…

We are rubber tubing experts, and we have been since our founding in 1954. We serve the entire world with quality tubing products right from the heart of Pennsylvania.

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

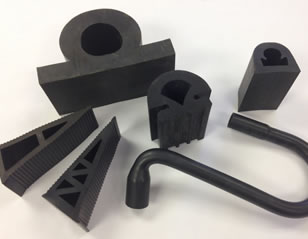

Manufacturer of standard and custom rubber tubing. Made of EPDM, neoprene, nitrile, dense, recovery sponge rubber and silicone compounds. Secondary processes such as die cutting, notching, and glue splicing are offered.

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

Since 1963, we have concentrated on elastomers. Specifically, we are a full service custom rubber tubing manufacturer that produces engineered high performance elastomers such as extrusions, moldings, rubber tubing and custom assemblies. We offer silicone tubing in many compounds, as well as rubber hose, Viton tubing and EPDM tubing. Your tubing will be fabricated to exacting tolerances.

More Neoprene Tubing Manufacturers

Neoprene Tubing Production

Neoprene tubing is produced through a process that involves the synthesis of chloroprene and the subsequent polymerization of the rubber material. The polymerization process involves the addition of various chemical agents to the chloroprene, which can be done through emulsion, solution, or suspension polymerization methods. The choice of method depends on the desired properties of the neoprene tubing and the production process.

Considerations Regarding Neoprene Tubing

There are some considerations regarding the use of neoprene tubing, such as health concerns, environmental impact, and production issues. Neoprene is considered safe for use in products that come into contact with the skin, but prolonged exposure can cause skin irritation. Neoprene production can also have environmental consequences due to the release of chemicals during the manufacturing process. Finally, neoprene production can be energy-intensive, and the disposal of waste products can also be challenging.

Benefits of Neoprene Tubing

One of the main benefits of neoprene tubing is its excellent resistance to oils, chemicals, and abrasions. This makes it an ideal material for use in harsh environments where other types of tubing might break down or deteriorate over time. Neoprene tubing is also highly resistant to weathering and UV radiation, which makes it suitable for outdoor applications. Another advantage of neoprene tubing is its flexibility and elasticity. Neoprene can be stretched and compressed without losing its shape or functionality, which makes it ideal for applications where the tubing needs to bend or flex without breaking. Neoprene also has good compression set resistance, which means it can retain its shape even after being compressed for long periods of time.

Neoprene tubing also has good insulation properties, which makes it suitable for use in electrical and electronic applications. It can help to protect wires and cables from damage, and can also provide a barrier against heat and cold. Finally, neoprene tubing is generally easy to work with and install. It can be cut to size with standard tools, and can be easily connected to other tubing or fittings using standard clamps or connectors. It also has good resistance to kinking, which can help to prevent blockages and damage to the tubing. Overall, neoprene tubing is a versatile and reliable material that can be used in a wide range of applications where resistance to harsh environments, flexibility, and insulation are important factors.

Applications of Neoprene Tubing

As a result of its many beneficial properties, neoprene tubing has several applications in various industries, including:

Industrial Applications

Neoprene tubing is commonly used in industrial applications such as automotive, manufacturing, and oil and gas industries. Its resistance to oils, chemicals, and abrasion make it ideal for use in these harsh environments where it can protect cables, wires, and hoses from damage.

Medical Applications

Neoprene tubing is also used in medical applications where it can provide a barrier against fluids and can be easily sterilized. It is commonly used in medical devices such as catheters, IV lines, and surgical tubing.

Sports and Fitness Applications

Neoprene tubing is used in a variety of sports and fitness equipment such as resistance bands, weightlifting belts, and exercise machines. Its flexibility, elasticity, and resistance to weathering make it ideal for use in these applications.

Electrical and Electronic Applications

Neoprene tubing is commonly used in electrical and electronic applications where it can provide insulation and protect wires and cables from damage. It can also provide a barrier against heat and cold and is commonly used in wiring harnesses, power cords, and computer cables.

Marine Applications

Neoprene tubing is also used in marine applications where it can provide a barrier against saltwater and UV radiation. It is commonly used in boat covers, dock lines, and other marine equipment.

Aerospace Applications

Neoprene tubing is also used in the aerospace industry where it can provide a barrier against heat, cold, and radiation. It is commonly used in aerospace equipment such as satellites, rockets, and spacecraft.

Choosing The Correct Neoprene Tubing Supplier

To ensure you have the most beneficial outcome when purchasing neoprene tubing from a neoprene tubing supplier, it is important to compare several companies using our directory of neoprene tubing suppliers. Each neoprene tubing supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each neoprene tubing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple neoprene tubing companies with the same form.

Rubber Extrusions

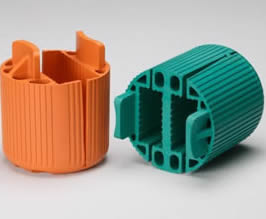

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

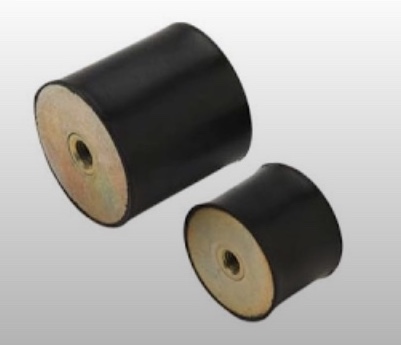

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services