Natural rubber is derived from natural latex and synthetic rubber comes from processed petrochemicals; the term gum rubber refers the naturally derived version. Gum rubber tubing can range in outer diameter, inner diameter and wall thickness. It is usually tan or white in color; colorants may be added, though this interferes with the purity of the rubber. Read More…

We are rubber tubing experts, and we have been since our founding in 1954. We serve the entire world with quality tubing products right from the heart of Pennsylvania.

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

Manufacturer of standard and custom rubber tubing. Made of EPDM, neoprene, nitrile, dense, recovery sponge rubber and silicone compounds. Secondary processes such as die cutting, notching, and glue splicing are offered.

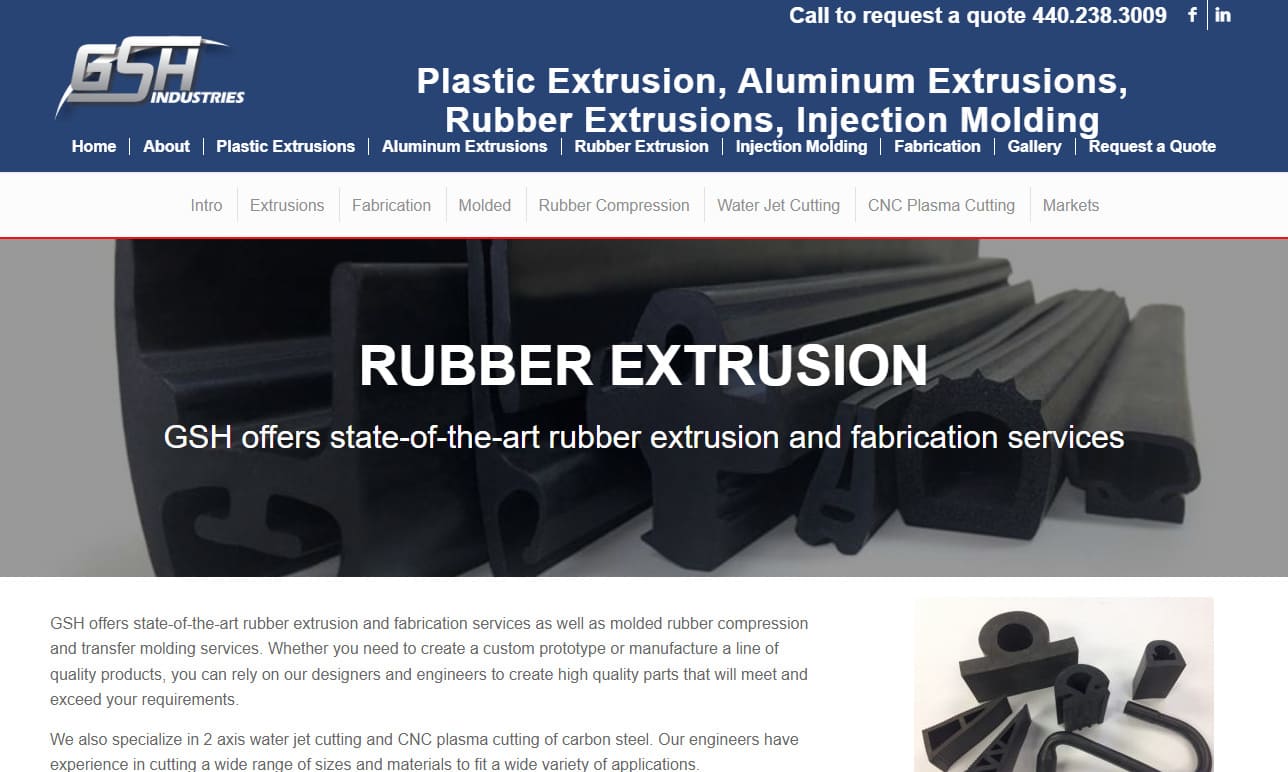

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

Since 1963, we have concentrated on elastomers. Specifically, we are a full service custom rubber tubing manufacturer that produces engineered high performance elastomers such as extrusions, moldings, rubber tubing and custom assemblies. We offer silicone tubing in many compounds, as well as rubber hose, Viton tubing and EPDM tubing. Your tubing will be fabricated to exacting tolerances.

More Gum Rubber Tubing Manufacturers

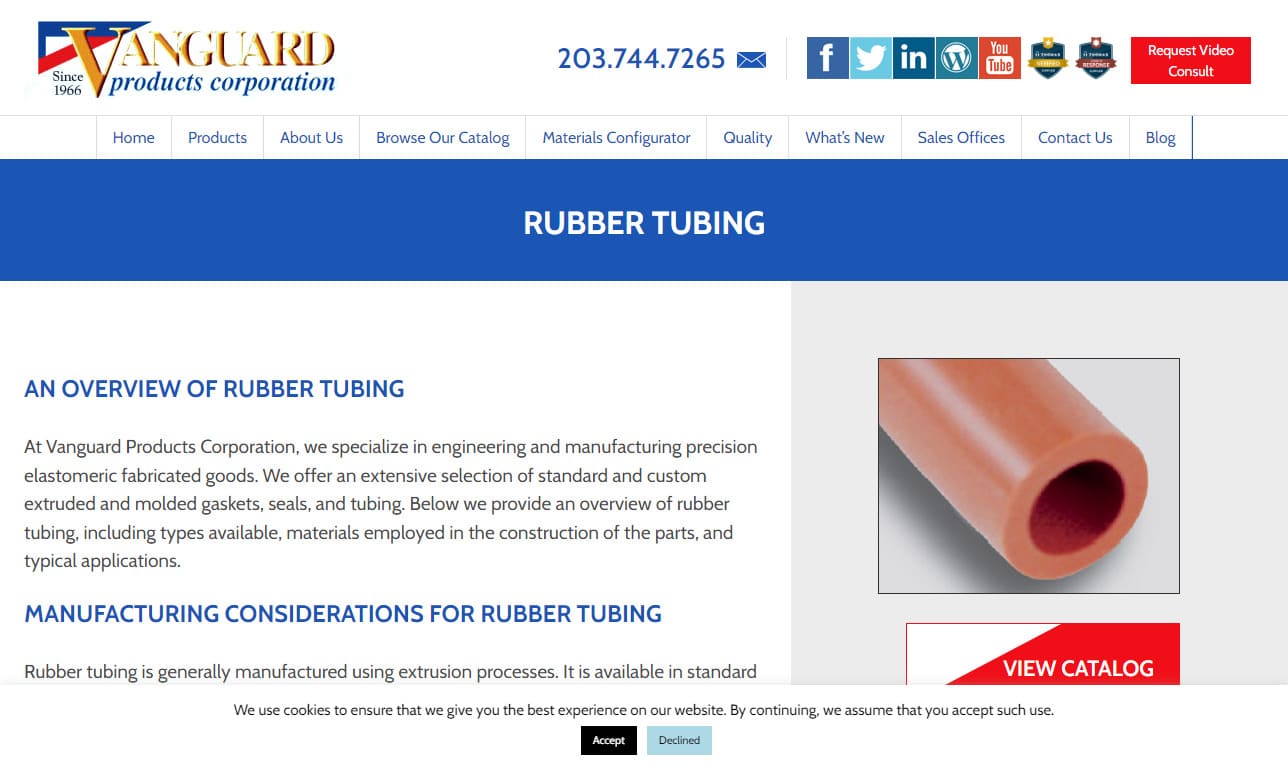

Gum rubber tubing has excellent tensile strength as well as being tear resistant and resilient. It retains its flexibility at low temperatures, making it weather and ozone resistant, and it has superior shape memory. Gum rubber tubing is used in many industries for a variety of applications including dry bulk food processing in addition to pharmaceutical, chemical, hydraulic, pneumatic and specialty applications.

It is also widely used in laboratories and medical environments because it permits unrestricted flow of water, gases, chemicals and acids at low pressure. It has a tight seal when connected correctly to push-on fittings, hose barbs and glass tubing. Gum rubber tubing may also be used in vacuum assemblies when the wall thickness is at least half the internal diameter.

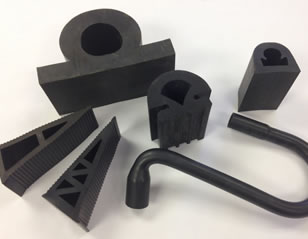

Gum rubber is made from natural latex. The collected natural latex is taken to a processing plant and mixed with chemicals so it thickens. In synthetic rubber, certain additives can influence the attributes of the final product. For example, some rubber tubing is conductive while other tubing is sterile and inert. Neoprene, silicone and Viton are a few examples of materials that have different characteristics while still being classified as rubber tubing. For instance, neoprene is buoyant, silicone is very smooth and elastic and Viton tubing is highly resilient. After mixing, the rubber must be given its shape.

There are three main ways this is done: molding, extrusion and dipping. Liquid rubber can be poured into molds and pressed into place; the two halves will later be attached and smoothed together. Rubber tube extrusion involves taking raw rubber materials and forcing them through an extrusion die. Dipping rubber tubes involves long cylinders called mandrels whose thickness is the width of the desired internal diameter. They are dipped into vats of rubber and then dried and steam cured. For a textured non-slip exterior, gum rubber tubing may be wrapped in cloth.

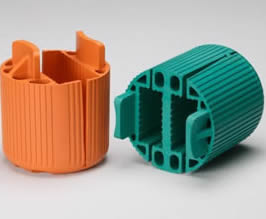

Rubber Extrusions

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

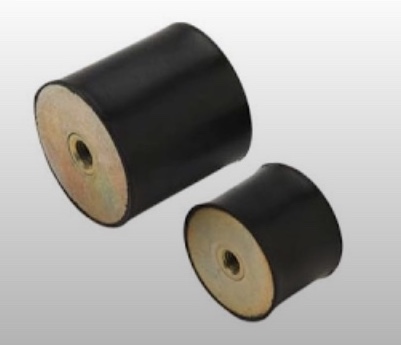

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services