EPDM tubing is a type of rubber tubing that has become increasingly important in various industries due to its versatility and durability. In this article, we will discuss what EPDM tubing is, how it is created, considerations regarding its manufacture and use, its benefits, and many of its various applications. Read More…

We are rubber tubing experts, and we have been since our founding in 1954. We serve the entire world with quality tubing products right from the heart of Pennsylvania.

As the largest in-house pure gum inventory carrier in the U.S., Atlantic Rubber Company has cost-effective and resilient rubber tubing. We carry a variety of materials so that we can make the best product for your needs.

Manufacturer of standard and custom rubber tubing. Made of EPDM, neoprene, nitrile, dense, recovery sponge rubber and silicone compounds. Secondary processes such as die cutting, notching, and glue splicing are offered.

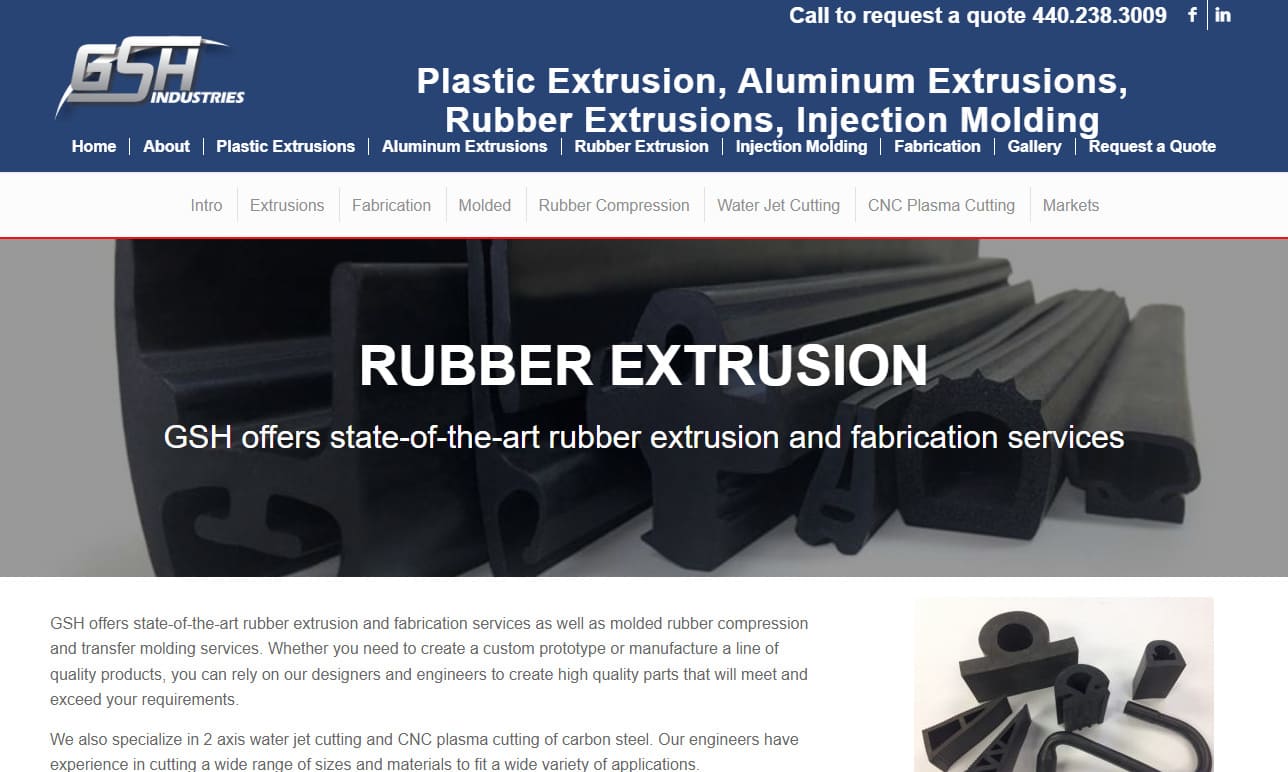

Established in 1986, GSH Industries supplies plastic, aluminum and rubber tubing to an array of industries including automotive, consumer, marine and electrical.

Since 1963, we have concentrated on elastomers. Specifically, we are a full service custom rubber tubing manufacturer that produces engineered high performance elastomers such as extrusions, moldings, rubber tubing and custom assemblies. We offer silicone tubing in many compounds, as well as rubber hose, Viton tubing and EPDM tubing. Your tubing will be fabricated to exacting tolerances.

More EPDM Tubing Manufacturers

What Is EPDM Tubing?

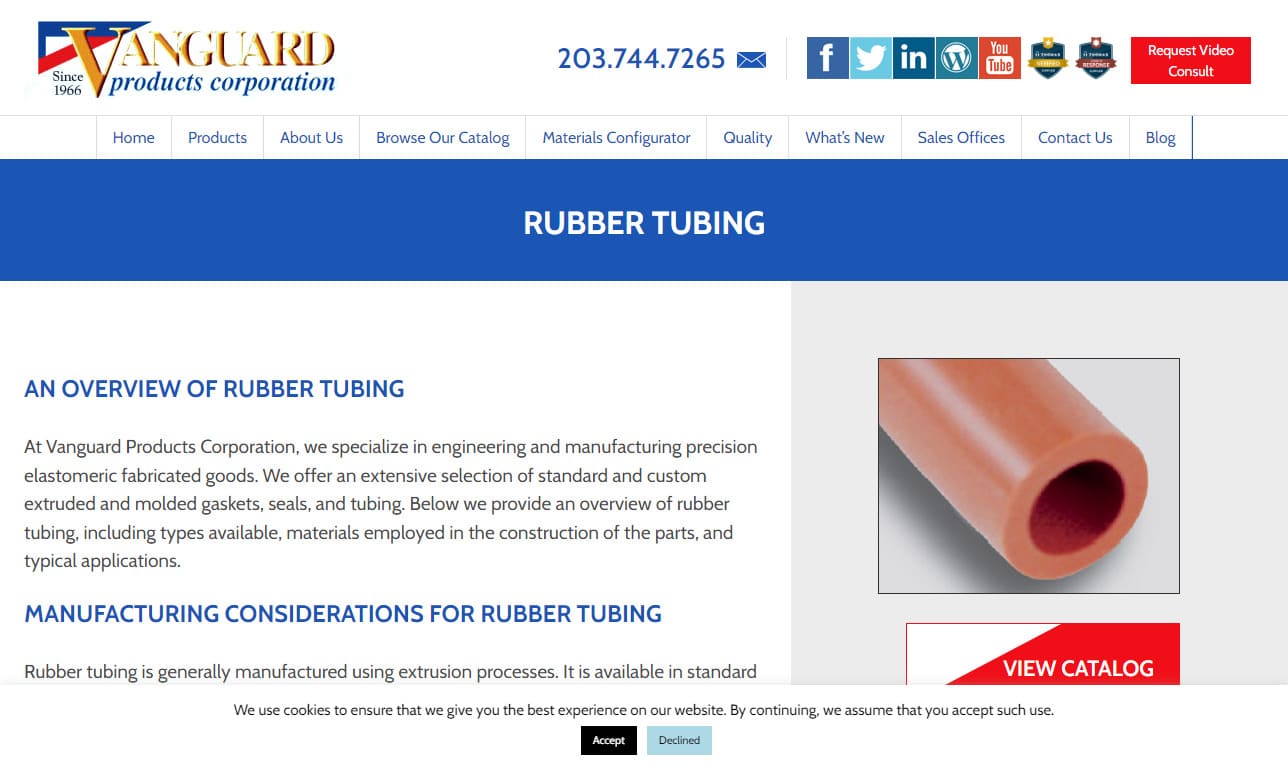

EPDM tubing, also known as Ethylene Propylene Diene Monomer tubing, is a type of synthetic rubber that is primarily used in applications that require resistance to heat, weather, and ozone. It is also known for its flexibility, low permeability, and excellent insulation properties. EPDM tubing is commonly used in industries such as automotive, chemical processing, food and beverage, HVAC, and renewable energy.

How Is EPDM Tubing Created?

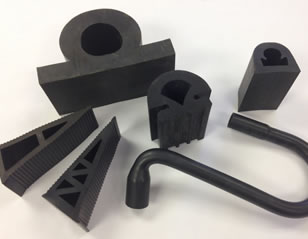

The creation of EPDM tubing involves several steps. First, raw materials such as ethylene, propylene, and diene monomer are mixed together and then polymerized to create EPDM rubber. The EPDM rubber is then mixed with a cross-linking agent and other additives, depending on the intended application of the tubing. The mixture is then extruded into tubing form and vulcanized to create the final product.

There are various methods available to create EPDM tubing, each with its own benefits and drawbacks. One of the most common methods is the extrusion process, which involves melting the raw materials and forcing them through a die to create the desired shape. Another method is the co-extrusion process, which involves extruding multiple layers of different materials to create a tubing with different properties.

The choice of EPDM tubing creation method will depend on the specific application requirements. For instance, the extrusion process is typically used for producing EPDM tubing with a uniform wall thickness, while the co-extrusion process is ideal for creating tubing with a combination of properties such as chemical resistance, UV resistance, and flexibility.

Considerations Regarding EPDM Tubing

While EPDM tubing has several benefits, there are also potential negatives to consider. For instance, EPDM tubing may not be suitable for certain applications that require extreme chemical resistance or high-temperature tolerance. Additionally, certain formulations of EPDM tubing may be prone to premature aging or cracking over time.

Additionally, the use of chemical additives in the manufacturing process which may be harmful to the environment if not handled and disposed of properly. Prolonged exposure to certain chemicals used in the manufacturing process, such as sulfur, may cause skin or respiratory irritation. Also, the potential for EPDM tubing to release volatile organic compounds (VOCs) into the environment, although the level of VOC emissions is generally considered to be low.

Benefits of EPDM Tubing

Despite these limitations, the benefits of EPDM tubing outweigh the negatives. One of the most significant advantages is its excellent resistance to heat, ozone, and UV light. It is also highly flexible, making it easy to install and handle. Additionally, EPDM tubing has a wide range of temperature tolerance, making it suitable for use in both high and low-temperature environments.

Furthermore, EPDM tubing is chemically inert, meaning it can withstand exposure to corrosive chemicals without degrading or reacting. Its low permeability also makes it ideal for use in fluid transfer applications. EPDM tubing's insulation properties also make it an ideal material for use in HVAC and refrigeration systems.

Applications of EPDM Tubing

The various applications of EPDM tubing are numerous, and they continue to expand as new industries emerge. Some more common applications of EPDM tubing today include:

Automotive Industry

EPDM tubing is used extensively in the automotive industry for fluid transfer applications, including coolant and fuel lines. It is particularly well-suited for these applications due to its resistance to heat, weathering, and chemicals.

HVAC Industry

EPDM tubing is commonly used in heating, ventilation, and air conditioning (HVAC) systems for the transfer of fluids and gasses. It is preferred over other materials due to its ability to withstand high temperatures and its excellent insulation properties.

Food and Beverage Industry

EPDM tubing is often used in the food and beverage industry for applications such as milk and beverage dispensing, as well as for the transfer of food-grade liquids. EPDM tubing is FDA-approved for use in contact with food, and its smooth surface makes it easy to clean and sanitize.

Pharmaceutical Industry

EPDM tubing is commonly used in the pharmaceutical industry for the transfer of fluids and gasses in drug manufacturing and processing applications. It is preferred over other materials due to its resistance to chemicals and its ability to maintain purity.

Chemical Industry

EPDM tubing is widely used in the chemical industry for the transfer of aggressive chemicals such as acids and alkalis. It is preferred over other materials due to its excellent resistance to chemicals and its durability.

Construction Industry

EPDM tubing is used in the construction industry for applications such as water drainage and insulation. Its weather-resistant properties make it well-suited for outdoor applications such as roofing and waterproofing.

Renewable Energy Industry

EPDM tubing is used in solar thermal systems for the transfer of fluids such as water and glycol. It is preferred over other materials due to its resistance to high temperatures and its ability to maintain flexibility in cold temperatures.

Choosing the Proper EPDM Tubing Manufacturer

To ensure you have the most positive outcome when purchasing EPDM tubing from a EPDM tubing manufacturer, it is important to compare several companies using our directory of EPDM tubing manufacturers. Each EPDM tubing manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each EPDM tubing business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple EPDM tubing companies with the same form.

Rubber Extrusions

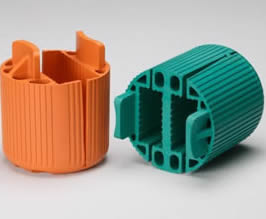

Rubber Extrusions Rubber Molding

Rubber Molding Rubber to Metal Bonding

Rubber to Metal Bonding Rubber Tubing

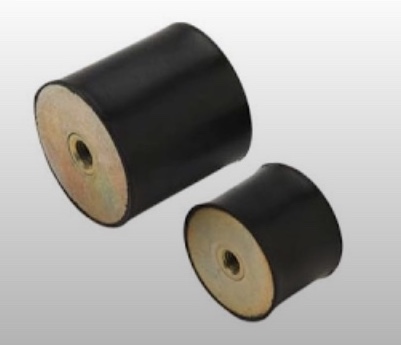

Rubber Tubing Vibration Absorbers

Vibration Absorbers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services